Advancing Medical Device Performance with Reliable Connectors #

Medical connectors are essential components that ensure the seamless operation and dependability of a wide range of medical devices. At Cambus Corporation, we have been dedicated to the design, testing, and manufacturing of both standard and custom medical connectors since 1997. Our expertise extends from supporting innovative start-ups to partnering with established industry leaders, with a primary focus on custom solutions tailored to specific medical applications.

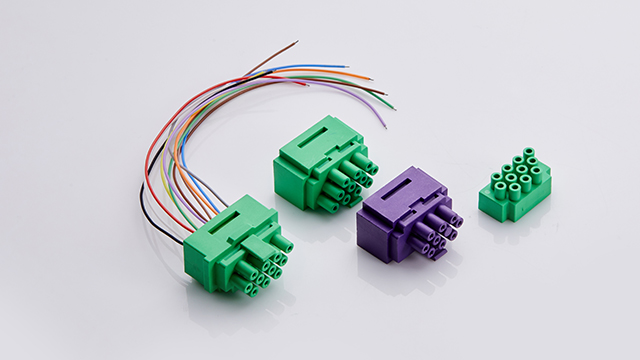

ECG Receptacle Cable Connector with Wire Harness

ECG Receptacle Cable Connector with Wire Harness

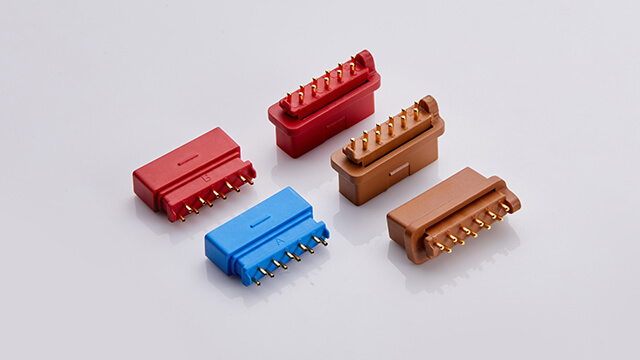

Male Pin Header connector – 11P

Male Pin Header connector – 11P

Patient interface connector (PIC)

Patient interface connector (PIC)

AO1 & AO2 Connectors

AO1 & AO2 Connectors

Dsub 15P connector with FPC assembly – waterproof

Dsub 15P connector with FPC assembly – waterproof

Lemo & Redel Substitute Connectors (Metal)

Lemo & Redel Substitute Connectors (Metal)

Lemo & Redel Substitute Connectors (Plastic)

Lemo & Redel Substitute Connectors (Plastic)

Commitment to Quality and Industry Standards #

Our medical equipment connectors are engineered to meet the rigorous quality and reliability requirements of the medical device sector. These connectors play a pivotal role in applications such as patient monitoring, magnetic resonance imaging, diagnostic imaging, and electrocardiogram systems. Cambus connectors are recognized for their durability, extended lifespan, and resistance to harsh medical cleaning agents, supporting the development of compact, lightweight, and mobile medical devices that enhance patient care.

We also offer hybrid connector solutions that integrate data, power, and even gas or fluid channels into a single, high-density connector—optimizing both the size and weight of medical equipment.

Tailored Custom Medical Connector Solutions #

One of our core strengths lies in providing custom medical connector manufacturing services. Custom connectors are often essential for applications that demand unique designs, ensuring compatibility and safety by allowing only specific cables or connectors to interface with a device. These solutions are meticulously crafted to match the physical and functional requirements of the target medical device, often combining multiple signal types within a single connector.

While custom connectors may involve initial engineering and mold development costs, they frequently result in lower total costs compared to standard alternatives, especially when considering long-term reliability and device integration. Cambus is committed to delivering custom solutions that align precisely with your project specifications.

Ensuring Patient Safety and Regulatory Compliance #

Patient safety is our foremost priority. Cambus is certified to ISO 13485:2016, ensuring that our quality management systems for medical device components meet international standards. Our connectors are designed to safely deliver power to hand tools and diagnostic equipment, while reliably transmitting signals to consoles and surgical systems.

By selecting the appropriate connector and cable assembly, manufacturers can create devices that are not only safe and functional but also cost-effective and user-friendly. Our solutions help minimize risk for both patients and healthcare professionals, while streamlining the development process and supporting regulatory compliance.

Cambus remains dedicated to providing both standard and custom connector solutions that advance the performance and reliability of medical devices, ultimately contributing to improved patient outcomes and healthcare innovation.

For further information or to discuss your specific connector requirements, please contact Cambus.